Izinzuzo Nemikhawulo Yokubumba Umjovo

Izinzuzo zokubumba umjovo phezu kokubunjwa kwe-die cast kuye kwaphikiswana ngakho kusukela inqubo yangaphambili yethulwa okokuqala ngeminyaka yawo-1930. Kukhona izinzuzo, kodwa futhi ukulinganiselwa endleleni, futhi ukuthi, ngokuyinhloko, kusekelwe isidingo. Abakhiqizi bemishini yoqobo (i-OEM) nabanye abathengi abathembele ezingxenyeni ezibunjiwe ukuze bakhiqize izimpahla zabo, bafuna izici ezifana nekhwalithi, ukuqina kanye nokufinyeleleka ekuthengeni ukuze banqume ukuthi yiziphi izingxenye ezibunjiwe ezifanelana kangcono nezidingo zabo.

KUYINI UKUBONGA UMJOVA?

Ukubumba umjovo kuyindlela yokwenza izingxenye eziqediwe noma imikhiqizo ngokuphoqelela ipulasitiki encibilikisiwe ibe isikhunta bese uyiyeka iqine. Ukusetshenziswa kwalezi zingxenye kuyehluka kakhulu njengezinhlobonhlobo zemikhiqizo eyenziwe ngenqubo. Kuye ngokusetshenziswa kwawo, izingxenye ezibunjwe ngomjovo zingaba nesisindo esisuka kuma-ounces ambalwa sifike emakhulwini noma ezinkulungwaneni zamaphawundi. Ngamanye amazwi, kusukela ezingxenyeni zekhompiyutha, amabhodlela e-soda namathoyizi, kuya elolini, ugandaganda kanye nezingxenye zezimoto.

YINI I-DIE CASTING

I-Die casting iyinqubo yokukhiqiza yokukhiqiza izingxenye zensimbi ezinobukhulu obunembile, ezichazwe ngokucijile, ezibushelelezi noma ezithungwe. Kufezwa ngokuphoqelela insimbi encibilikisiwe ngaphansi kwengcindezi ephezulu ibe yinsimbi engasetshenziswa kabusha. Inqubo ivame ukuchazwa njengebanga elifushane kakhulu phakathi kwempahla eluhlaza nomkhiqizo ophelile. Igama elithi “die casting” libuye lisetshenziswe ukuchaza ingxenye eqediwe.

UKUBONGA UMjovo WEPlastiki VS. I-DIE CASTING

Indlela yokubumba umjovo ekuqaleni yayimodela ekufakweni kwe-die casting, inqubo efanayo lapho insimbi encibilikisiwe iphoqelelwa ukuba ibe isikhunta ukuze ikhiqize izingxenye zemikhiqizo ekhiqiziwe. Kodwa-ke, esikhundleni sokusebenzisa ama-resin epulasitiki ukukhiqiza izingxenye, i-die casting isebenzisa ikakhulukazi izinsimbi ezingenayo insimbi njenge-zinc, i-aluminium, i-magnesium, nethusi. Nakuba cishe noma iyiphi ingxenye ingaphonswa cishe kunoma iyiphi insimbi, i-aluminium iye yavela njengenye edume kakhulu. Inephuzu eliphansi lokuncibilika, okwenza kube lula ukubumba izingxenye. Ama-dies anamandla kunesikhunta esisetshenziswa enqubweni yokufa unomphela ukumelana nemijovo yokucindezela okukhulu, okungaba ngu-30,000 psi noma ngaphezulu. Inqubo yokucindezela okuphezulu ikhiqiza isakhiwo esiqinile, sebanga elihle elinamandla okukhathala. Ngenxa yalokhu, ukusetshenziswa kwe-die casting kuyahlukahluka kusuka kwezinjini nezingxenye zenjini kuya emabhodweni namapani.

Izinzuzo Zokusakaza ze-Die

I-Die casting ilungile uma izidingo zenkampani yakho ziqinile, eziqinile, izingxenye zensimbi ezikhiqizwe ngobuningi njengamabhokisi ahlanganayo, amapiston, amakhanda amasilinda, namabhulokhi enjini, noma ophephela, amagiya, amabhushi, amaphampu, namavalvu.

Iqinile

Okuhlala isikhathi eside

Kulula ukukhiqiza ngobuningi

Imikhawulo Yokusakaza Ifa

Nokho, ngokungangabazeki, nakuba i-die casting inezinzuzo zayo, kunenani lemikhawulo endleleni okufanele icatshangelwe.

Osayizi bezingxenye ezinomkhawulo (ubukhulu obungama-intshi angu-24 nama-lbs angu-75.)

Izindleko zamathuluzi zokuqala eziphezulu

Izintengo zensimbi zingashintsha kakhulu

Izinto ezilahliwe zengeza ezindlekweni zokukhiqiza

Izinzuzo zokubumba umjovo

Izinzuzo zokubumba umjovo ziye zazuza ekudumeni phakathi neminyaka ngenxa yezinzuzo ezinikezayo ngaphezu kwezindlela zokukhiqiza ze-die casting. Okungukuthi, inani elikhulu nezinhlobonhlobo zezindleko eziphansi, imikhiqizo ethengekayo eyenziwe ngamapulasitiki namuhla ayinamkhawulo. Kukhona nezidingo zokuqeda ezincane.

Isisindo esilula

Ukumelana nomthelela

Ukumelana nokugqwala

Ukumelana nokushisa

Izindleko eziphansi

Izidingo zokuqeda ezincane

Sekwanele ukusho, ukukhetha ukuthi iyiphi indlela yokubumba ozoyisebenzisa ekugcineni izonqunywa ukuphambana kwekhwalithi, isidingo, kanye nenzuzo. Kunezinzuzo kanye nemikhawulo endleleni ngayinye. Iyiphi indlela ongayisebenzisa—ukubumba i-RIM, ukubumba okujwayelekile komjovo noma ukufaniswa kwengxenye yokukhiqiza—kuzonqunywa izidingo ze-OEM yakho.

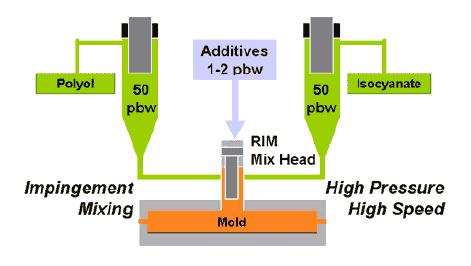

I-Osborne Industries, Inc., isebenzisa inqubo yokubumba umjovo wokusabela (RIM) ngaphezu kwezinqubo zokubumba umjovo ezivamile ngenxa yezindleko zayo eziphansi ngisho nangokwengeziwe, ukuqina, nokuguquguquka kokukhiqiza indlela enikezela ngayo kuma-OEM. I-RIM-molding ifaneleka ekusetshenzisweni kwepulasitiki ye-thermoset ngokuphambene ne-thermoplastics esetshenziswa ekubumbeni umjovo wendabuko. Amapulasitiki e-Thermoset anesisindo esilula, aqine kakhulu futhi amelana nokugqwala, futhi alungele ikakhulukazi izingxenye ezisetshenziswa emazingeni okushisa adlulele, ukushisa okuphezulu, noma izinhlelo zokusebenza ezigqwala kakhulu. Izindleko zokukhiqiza ingxenye ye-RIM ziphansi, futhi, ngisho nokugijima kwevolumu emaphakathi nephansi. Enye yezinzuzo ezinkulu ekubunjweni komjovo ukuthi kuvumela ukukhiqizwa kwezingxenye ezinkulu, njengamaphaneli amathuluzi emoto, iziqongo zombhoshongo weseli ye-chlorine, noma izinsimbi zamaloli ne-trailer.

Isikhathi sokuthumela: Jun-05-2020