Ukudizayina okukhethekile kwamakhiphedi enjoloba angokwezifiso

Uma ukhiqiza ikhiphedi ye-silicone yangokwezifiso, qaphela indlela okhiye bakho abazolebula ngayo noma bamakwe ngayo.Imiklamo eminingi yekhiphedi ayidingi ukumakwa, njengamakhiphedi azobanjwa endaweni (enelebuli) yohlobo oluthile.Nokho, amakhiphedi amaningi adinga uhlobo oluthile lokumaka ukuze abone imisebenzi yokhiye ngamunye.Unezinketho eziningi ezahlukene uma kuziwa ekudaleni ukhiye, ngayinye enezinzuzo zayo ezihlukile.

Ukuphrinta

Ukuphrinta kuyindlela evame ukusetshenziswa kakhulu yokumaka amakhiphedi e-silicone nenjoloba, ikakhulukazi ngoba ishibhile futhi iguquguquka kakhulu ngemibala nobujamo obusetshenziswayo.Phakathi nenqubo yokuphrinta, ikhiphedi iyafinyezwa ukuze indawo yokuxhumana yephrinta ikwazi ukufaka ilebula phezulu kokhiye.Ngokuya ngokugoba kweziqongo zokhiye ozifunayo, ungakwazi ukuphrinta yonke indlela kuze kufike emaphethelweni kakhiye ngamunye.Ungakwazi futhi ukuphrinta ukugxila okwengeziwe ezikhungweni.

Okhiye abaphrintiwe bashibhile, kodwa futhi baguga ngokushesha.Ngokuhamba kwesikhathi ingaphezulu likakhiye lihujwa ngokunikezwa, futhi indawo ephrintiwe iyaguga.Kunezindlela ezimbalwa zokunweba impilo yokhiye abaphrintiwe.

1. Izigqoko zokuphela kwepulastiki zinganamathela ekugcineni kokhiye ngamunye, zinikeze okhiye ukuthungwa okuhlukile, kuyilapho kuvikela indawo yokhiye ekuhuzukeni.

2. Izingubo zikawoyela eziqongweni zezikhiye zenza izikhiye zibe nesiphetho esicwebezelayo.Baphinde bandise impilo yokunyathelisa.

3. I-Drip coating kanye ne-Parylene coatings isetshenziswa phezu kokhiye ngemva kokuphrinta.Lokhu kukhiqiza umgoqo phakathi kwendawo ephrintiwe nomsebenzisi ngaphandle kokudinga ikepisi lepulasitiki.Izembatho zandisa impilo yezikhiye, kodwa kufanele uhlole ukubekezelelana kwemvelo kwezingubo ngaphambi kokuthi uzisebenzise kwezinye izimo.

Ukukhishwa kwe-Laser

Ku-laser etching, indawo yerabha ye-silicone iphathwa ngejazi langaphezulu elikhanyayo eliqoshwe nge-laser ukuze kwakhiwe idizayini.Uma uqala ngesendlalelo sesisekelo esishintshashintshayo, lokhu kungaba inqubo yokulebula ewusizo kakhulu ukuze udale ikhiphedi ye-silicone ekhanyiswe ngemuva.Ukukhanya kuzokhanya ngelebula ngenkathi ivinjwe omunye ukhiye, okudala umphumela wokubukwayo owusizo.Izinketho zokumboza kanye ne-capping ziyefana ngokufakwa kwe-laser.Nakuba, njengoba ilebula empeleni AYIphrintiwe, ayiphoqelekile.

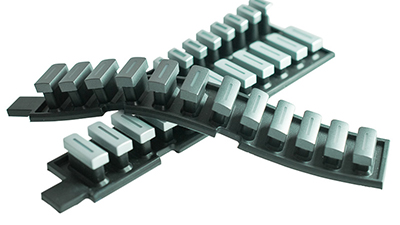

Izigqoko Zepulasitiki

Amakepisi epulasitiki kufanele asetshenziselwe izimo lapho impilo ende yekhiphedi ibalulekile.Izigqoko zokhiye bepulasitiki zingaklanywa zibe nezinombolo/amalebula abunjwe phezulu, noma abe nama-depression noma amapulasitiki anemibala ehlukile.

Amakepisi epulasitiki ayisixazululo esibiza kakhulu enkingeni esemqoka yokulebula.Kodwa futhi zilungele izimo lapho ikhiphedi izobona ukusetshenziswa okuningi kangangokuthi ukuphrinta okuvamile ngeke kusebenze.Uma ufuna ukusebenzisa amakepisi epulasitiki kumakhiphedi akho e-silicone, qiniseka ukuthi ipulasitiki oyisebenzisayo ayiqhubeki futhi izomelana nezinga lokushisa elifana nelo lonke ikhiphedi ye-silicone.

Ukucatshangelwa okwengeziwe

Uma unquma ngohlobo lwelebula lokhiye bakho, qiniseka ukwenza kanjalobonisananabaqambi nonjiniyela abangochwepheshe e-JWT Rubber.Sizosebenza nawe ukuze sithole ukuvumelana phakathi kwempilo ebalulekile kanye nokusebenza kahle kwezindleko.

Ikhiphedi yerabha ekhanyisa ngemuva

Ikhiphedi Yepulasitiki Nerabha

Isixazululo sekhiphedi Yerabha yangokwezifiso

I-PU enamathela

I-JWT Laser etching idivayisi

Ikhiphedi yerabha yokuphrinta usilika

Isikhathi sokuthumela: Jul-05-2020